獻給地球的計劃

2010年8月,我們發起了雀巢咖啡計劃(Nescafé Plan),承諾雀巢對咖啡的種植、生產和消費採用永續方式經營。雀巢咖啡計劃制定一連串的目標,持續精進咖啡從生產直到採購的供應鏈

“雀巢的「責任種植(Grown Respectfully)」計劃是為了永續經營農產品而設立的。

在地咖啡農是高品質咖啡的靈魂。不幸地,氣候變遷、植物疾病和農村人口外移等狀況都威脅著農民的生計。責任種植計畫把農民放在首位

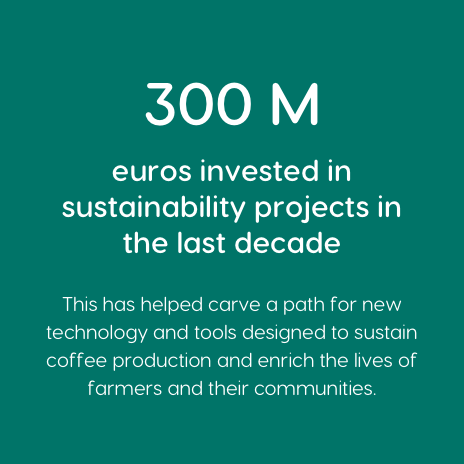

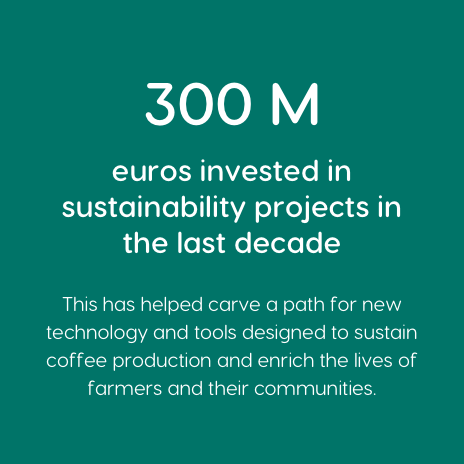

3億

歐元在近十年間投入永續計劃

相關投資讓創新科技和特殊設計工具得以支援咖啡生產,同時豐富農民和其社區的生活。

10萬名

咖啡經過訓練,了解永續經營的方法

我們與雨林聯盟合作,一同創建了《Nescafé Better Farming Practices》——一份有關咖啡農訓練的全球參考文件。

300位

農業顧問在全世界直接與咖啡農一起工作

我們的農民關懷計畫讓我們與農民和其協作者持續保持聯繫。

2億

更強壯和帶來更多收成的咖啡植物

會在今年底前提供給雀巢的咖啡農。

我們將在年底前,為雀巢咖啡農提供2億2千萬株更強壯和帶來更多收成及獲利的咖啡苗。

強大的合作伙伴讓雀巢更加壯大

生活是如此,咖啡的採購也是如此

咖啡保障聯盟

我們與咖啡保障系統的合作(CAS),確保雀巢採購的咖啡是經過責任耕種,並且符合國際承認的「4C」永續咖啡生產方式。

雨林聯盟

我們持續發展責任種植(Grown Respectfully program)與採收計劃的同時,與雨林聯盟一直保持策略合作伙伴關係 我們共同發展監督評估系統,以便持續評估永續發展對於種植區域的影響。

在雀巢多趣酷思膠囊咖啡中,100%的咖啡均來自責任採購。我們的目標是以責任採購方式,採購我們的全部的咖啡需求。

智慧化的供應鏈

與我們一起進入永續的生活循環

耕作

生產

經銷

消費

生命周期結束

耕作

生產

經銷

消費

生命周期結束

重視農民

我們因應各地需求,提供農民而設的特定訓練內容。自2010年以來,已經有超過7萬6千名農民接受了農業最佳成功案例訓練。

重視農作物

自2010年以來,分配給農民的高產量植物超過3千萬株。我們持續研究有潛力大幅提高產量的新咖啡品種。

了解我們如何將最優質的咖啡豆變成您杯中的美味咖啡。

您附近的回收站

以防您沒注意到,您可以在這裡了解在西班牙如何回收膠囊。

在家使用綠色袋子

在離您最近的回收點

探索雀巢在西班牙的永續目標。

對更加永續的未來,我們的承諾永遠不會結束。

加入我們的行列,給予地球應得的關懷與呵護。

膠囊咖啡機使用教學

膠囊咖啡機使用教學